The hammers are one of the most important parts of a piano. Their shape, density, texture and weight are all important to getting a good tone out of your instrument. Piano hammers are made of layers of dense felt over a core of wood. The top layers of felt are the softest, moving to harder layers towards the core. Over years of playing, the hammers, which start out rounded, or a little pointed at the strike-point, develop grooves where the strings contact, and eventually become flat. As the hammer gets more flat, the point of contact between the hammer and the string grows from a few millimeters to 1-2 centimeters. As that strike point gets bigger, your quality of tone decreases. In extreme cases, the grooves in the hammer become so deep, you can actually hear the strings rubbing against the walls of the grooves as the hammer hits and falls away from the string.

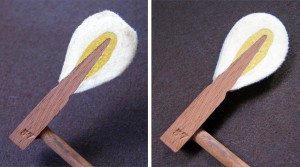

Piano hammers should be shaped several times through the life of the piano to maintain good tone and give the player good control. When I reshape hammers, I carefully remove layers of felt with different sanding paddles, working mostly on the shoulders of the hammer until I restore a focused strike-point. Since the inner felt is denser and harder than the outer layers, voicing is necessary after hammer shaping, or the tone will be much brighter than before, or in extreme cases, brittle or tinny.

Hammer voicing consists mostly of careful and judicious needling around the shoulders of the hammer to loosen or “fluff up” the felt. A hammer voicing tool has from 1 to 3 needles about 1 centimeter long.

The last step in hammer shaping is matching the hammer to the string. Most notes on the piano have three strings that all sound in unison. The hammer has to strike all three at precisely the same time to get optimal tone. If the strike-point of the hammer is a little crooked, or one string is higher or lower than the other two, not all strings will be struck with the same force. This can cause all sorts of odd sounds from a ringing echo sound to annoying buzzes or vibrations. So I will match each hammer to the strings to make sure it is meeting all three strings simultaneously, and if not, I will use my 1000 grit sanding paddle to shape the hammer to perfection.

This process can be done several times through a piano’s life if there is enough felt left on the hammers. Eventually the hammers will become too light to get a good sound, or will be worn down to the wood core, and then the hammers have to be replaced.

If your piano’s tone has deteriorated over the past years, it may need its hammers shaped. You can visually check for grooves on your hammers. If the grooves are getting long, or deep, you could be getting a better sound out of your piano with some hammer maintenance.